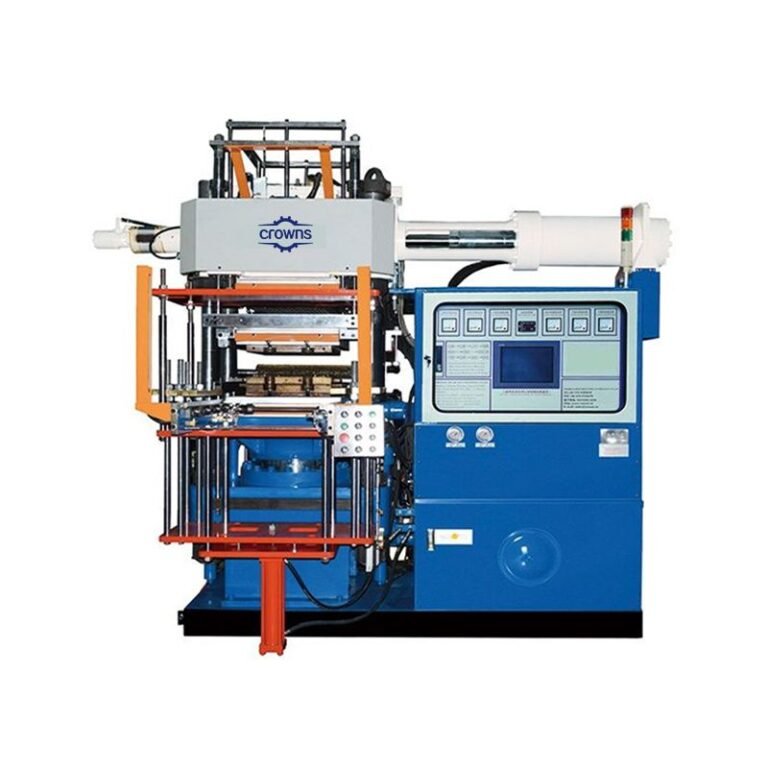

Rubber Injection Machine

Home » Rubber Injection Machine

Revolutionise your rubber production process with Crowns Machinery’s state-of-the-art rubber injection machine. Crowns Machinery is an innovative manufacturer that offers precise solutions for modern industry. Our machines will improve your production standards for automotive parts or industrial products.

Rubber Injection Machine For Sale

The Rubber Injection Machine is designed for making rubber parts using molten rubber. It injects the rubber into a mould to create precise and complex products. The equipment is very precise and can make consistent rubber parts. It can also improve productivity. The main components include injection device, clamping device, heating and cooling system, etc.

A mould is an important part of the rubber injection moulding process. It is usually made of metal and has two halves that are joined together during injection. It can determine the final shape and size of the rubber product.

Technical characteristics

Design of injection unit: It can realize high-precision and high-efficiency rubber injection.

Precise temperature control system: ensures that the rubber material reaches the proper melting state before injection.

High-pressure injection: Provide enough pressure to ensure that the rubber material is filled in the mold.

Closed-loop control system: real-time monitoring of temperature, pressure, injection speed, and other key parameters.

Automation and intelligent control: automation of loading, opening, and closing the mold, and product demoulding.

Mold replacement: support rapid mould replacement to achieve diversified production.

Energy efficiency: optimize the heating and cooling system to reduce energy consumption.

Working Principle

This equipment uses injection molding to create products. First, the rubber is heated until it melts. Then, it is injected into a mold under high pressure to shape it. It includes key steps such as preparation of raw materials, melting and injection of rubber, and curing of materials.

Heating: The rubber is put into the heating chamber of the injection machine. It melts at a high temperature and becomes easier to inject.

Mould Clamping: The clamping device keeps the mold stable and closed when injecting at high pressure.

Mould design: The mould is used to shape the rubber material. It can have many cavities to make multiple parts at once.

Mould injection:Once the mould is closed, a screw or plunger pushes the molten rubber material into it. This injection unit controls the volume and speed of the material accurately.

Cooling and curing: Once the injection is done, the mould stays closed and the rubber cools and cures inside. The cooling system helps to speed up the curing process.

Finished product ejection: After the rubber is cured and formed, the clamping device is released. Then, the mold is opened and the product is ejected.

Rubber Injection Machine Features

High Precision: The rubber injection machine makes precise rubber products that meet design requirements. The injection process can precisely meet production needs for complex rubber parts.

Efficient production: Rubber injection machines have automated procedures, like rapid injection and cooling. They also have a disposable molding process. These features reduce secondary processing, improve efficiency, and lower costs.

Material diversification: The rubber injection machine is very versatile. It can make rubber products for many industries.

Energy-saving and environmental protection: The injection molding machine produces less waste, saves energy, and is environmentally friendly.

Adapt to mass production: Rubber injection molding machines are sustainable and produce many consistent products quickly. They are great for mass production.

Application

Rubber injection machines are used to manufacture a wide range of products, including automotive parts such as seals, gaskets, and O-rings, industrial components, medical devices, and consumer products, and are widely used in a variety of industries.

Automotive industry: manufacturing seals, engine parts, and other automotive parts.

Medical equipment industry: manufacturing medical gloves, medical hoses, and other medical equipment.

Electronic equipment: manufacture rubber parts for various electronic and electrical equipment.

Industrial components: Manufacture of rubber seals for various industrial purposes, etc.

Consumer goods industry: manufacturing various consumer goods such as shoe soles, toys, etc.

Construction industry: manufacturing rubber products needed in the construction industry, such as rubber mats, water stoppers, etc.

Maintenance and upkeep

In order to ensure that the equipment can operate for a long time and efficiently, regular maintenance and upkeep is crucial.

Regular cleaning: All parts of the injection machine should be cleaned regularly to remove residual foreign matter in order to prevent affecting the production quality.

Parameter calibration and adjustment: Regularly calibrate each parameter of the equipment, including temperature, pressure and injection speed, etc., to ensure that they are prepared correctly.

Maintenance of moulds: check the moulds regularly, clear the residual substances and repair the worn parts in time.

Lubrication system maintenance: Regularly check and lubricate the key parts of the equipment such as slides and screws to reduce wear and tear.

Heating system maintenance: clean the heating pipes and heating plates to prevent blockage.

Electrical system maintenance: check the electrical components and replace the aging and worn parts in time.

Safety system maintenance: regularly check the equipment’s safety door, emergency brake button and other safety devices to prevent accidents.