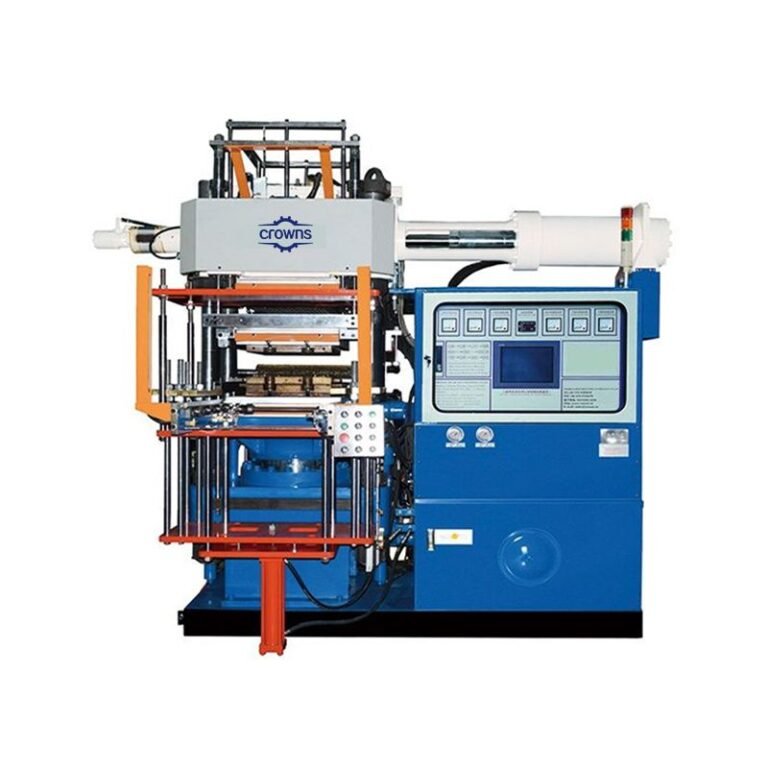

Horizontal Rubber Injection Machine

Home » Horizontal Rubber Injection Machine

Crowns Machinery prides itself on providing you with state-of-the-art solutions to enhance your production capabilities. From automotive parts to electronics, our Horizontal Rubber Injection Machine are backed by advanced technology to ensure top quality and reliability.

Horizontal Rubber Injection Machine For Sale

Horizontal Rubber Injection Machine is a kind of injection molding equipment used to produce rubber products, such as rubber seals, pipes, rubber gaskets, etc. The horizontal structure makes it easy to operate. Compared with the vertical injection machine, the injection unit and mold clamping unit of the horizontal injection machine are arranged horizontally, and the horizontal structure makes it convenient to operate with a large operating space and a small footprint.

The main structure of a horizontal injection machine includes an injection unit, mold clamping unit, mold, control system, and so on.

Parameters

| Model | RIM-100T | RIM-200T | RIM-300T | RIM-400T |

|---|---|---|---|---|

| Screw Dia.(φmm) | 30 | 40 | 50 | 50 |

| Plasticizing capacity(cm3/min) | 500 | 800 | 1000 | 1000 |

| Injection pressure (MPa) | 175 | 173 | 180 | 195 |

| Piston Dia.(φmm) | 70 | 80 | 95 | 95 |

| Injection Volume(cm3) | 1000 | 2000 | 3000 | 4000 |

| Mode locking force(KN) | 1000 | 2000 | 3000 | 4000 |

| Piston Stroke (mm) | 400 | 500 | 600 | 600 |

| Hot plate spacing(mm) | 450 | 570 | 750 | 750 |

| Min. mould thickness(mm) | 60 | 80 | 160 | 160 |

| Hot platen size(mm) | 450×450 | 540×580 | 700×600 | 800×700 |

| Electronic power(kW) | 12 | 12 | 18 | 18 |

| Working Pressure (MPa) | 20 | 20 | 20 | 20 |

| Motor Power(kW) | 7.5 | 11 | 15 | 15 |

| Installed power (KW) | 26 | 30 | 40 | 40 |

| Dimension(L×W×H)(m) | 3×1.9×3 | 3×2.3×4 | 3.4×2.3×4.4 | 3.6×2.8×4.8 |

| Total Weight(T) | 4 | 6 | 10 | 13 |

Working Principle

The working principle of the Horizontal Injection Molding Machine involves the steps of heating, injecting, cooling, and removing the rubber, and the injection process is controlled by setting the parameters of temperature, pressure, and injection speed as follows:

Heating: solid rubber granules or lump rubber will be put into the hopper of the injection machine, which will be heated and processed to transform it into a molten state that can be injected.

Injection: The rubber material, which has reached the molten state, is injected into the mold under the high-pressure push of the screw, filling every void in the mold evenly.

Cooling and curing: after the injection is completed, the mold remains closed under the action of the tightening unit, and the rubber is cooled and cured in the mold.

Mold opening: After the rubber has cured, the mold is opened by the mold clamping unit, and the final rubber product is taken out.

horizontal rubber injection machine Features

The advantages and features of the horizontal rubber injection molding machine over other types of injection molding machines make it more suitable for specific production requirements.

Stability and balance: The horizontal design allows the injection unit and the mold clamping unit to be located on the same horizontal plane, improving the stability and balance of the machine. It helps to ensure a uniform flow of rubber material during the injection process.

Space saving: A horizontal rubber injection machine occupies less height space than a vertical injection machine, which is more suitable for a production environment with space limitation.

Convenient operation: The design of a horizontal rubber injection machine makes it easier to install and replace the molds, which makes the operation more convenient, specially adapted to the situation where frequent replacement of molds or flexible adjustment of the production process is required.

Convenient maintenance: Horizontal injection machines are structurally separated from the injection unit and the mold clamping unit, making it easier to maintain the separate components, helping to reduce downtime and improve production efficiency.

More suitable for large molds: Horizontal injection machines are more stable in mold clamping, making them more suitable for handling large molds.

Precise temperature control: Horizontal rubber injection machines are equipped with an advanced temperature control system, which ensures product quality while increasing production efficiency under precise temperature control.

Intelligent and controllable: The system makes the operation of the machine more intelligent. The operator can easily set and monitor the parameters according to the production demand through the touch interface, improving the production process’s controllability.

Injection Machine Application

Rubber seals manufacturing: Horizontal rubber injection can be used to produce all kinds of rubber seals, such as rubber gaskets, O-rings and so on.

Rubber pipe fittings manufacturing: such as rubber hoses and rubber pipe joints applied in hydraulic system, industrial pipelines, etc.

Rubber gasket manufacturing: manufacturing for pipelines, valves, etc. to play the role of sealing and cushioning rubber gasket.

Rubber vibration isolator: used in construction, industrial equipment and other industries to reduce vibration and shock products.

Rubber soles: in the shoe industry, used to manufacture wear-resistant and elastic anti-slip rubber soles.

Rubber Cable Manufacturing: Used to manufacture insulation and protective coverings for rubber cables.